Over the years, the field of dentistry has witnessed an exciting amount of technological innovation. Now, with the progression of the digital age, rapid modernization has brought digital technology to the forefront of the dental industry. Practitioners are able to use a variety of digital technologies to lower costs, improve accuracy, and more. One of these technologies includes the use of additive manufacturing, also known as 3D printing. Here’s what you need to know about 3D printing applications in dentistry that are revolutionizing the way dental professionals run their practices.

How does 3D printing in dentistry work?

3D printing makes a physical object layer by layer from a CAD (computer aided design) or digital 3D model. Traditionally, dentists would have these models printed at a lab, but dental practices are increasingly investing in their own equipment to print in-house. According to a study done in 2017, dental offices spend an average of nearly $61,000 each year on lab expenses.

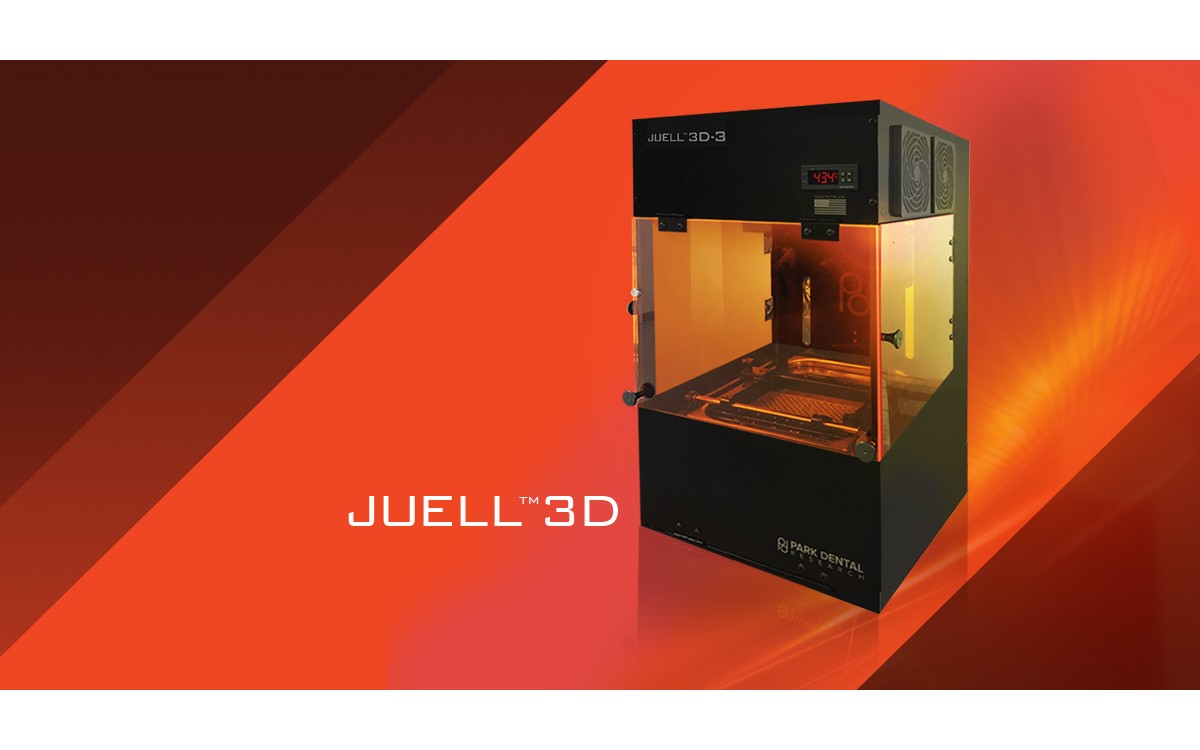

To cut costs and long wait times, dentists are using end-to-end digital dentistry solutions that eliminate the middleman. Having 3D printing technology in-office requires a desktop 3D printer, software, 3D printing materials (such as resins), and intraoral scanners. 3D printers, such as the JUELL™ 3D-3, can transform your practice.

What are the 3D printing applications in dentistry?

The dental 3D printing market is forecasted to be worth $7.98 billion by 2025 because of its widespread applications. Because each patient’s dentition is unique, the traditional method of producing dental items such as models or surgical guides can be time consuming. 3D printing provides a more accurate customization in a matter of minutes, allowing for faster and more efficient dental material production. Some of the most prominent applications include:

- Surgical guides/stents

3D printed surgical guides and stents provide a high rate of accuracy, therefore giving you greater reliability in surgery. A surgical guide that is 3D printed and placed over the patient’s teeth reduces the risk of hitting a nerve while drilling.

- Orthodontic models

This application gives you the precision you need when creating diagnostic aids. Produce viable results with convenience and ease, as 3D printing allows for modification—unlike injection molding. You can also use 3D printers for attachment templates and to print models for in-house aligner fabrication.

- Dental models

3D printing allows you to quickly create your patients’ dentition for study. When observing tooth and mouth structure for treatment preparation, you will get higher resolutions with greater accuracy.

- Indirect bonding trays

Traditional methods of applying braces are time consuming. With 3D printed trays, you don’t have to spend time on each individual tooth. Rather, you can bond an entire set of brackets at once for quick installation. Because of this, indirect bonding trays are considered a cost-effective and quick 3D printing application in dentistry.

- Castable parts

Replace traditional casting methods with 3D printing for a more efficient and scalable solution. Over 50 million castable parts are needed each year and having a better system in place can improve your workflow.

Every dental practitioner should be aware of not only the 3D printing applications in dentistry, but also the benefits accounting for its market growth and increased popularity.

What are the benefits of utilizing 3D printing in dentistry?

By integrating 3D printing applications in dentistry, you can simplify your workflow and eliminate the high costs of dental laboratories. Not only will this save dental practice money, it will also save patients money and reduce patient visits. Lab costs are reflected in each patient’s bill, and 3D printers can reduce these overhead costs by 80%. Although 3D printers require ongoing material costs, these lifetime costs added up are still significantly lower than outsourcing.

The improved accuracy, reliability, resolution, and outcomes for patients make 3D printing part of the ideal workflow for dentists. Your increased production capacity and reduction of labor saves time. Additionally, 3D printing helps save office space and lowers your risk of model deterioration. Because 3D printing uses digital files, storing and sharing your files with other clinicians is much easier. The 3D printing applications in dentistry offer promising advances for your office and are becoming the standard of patient care.

How is JUELL™ 3D leading the way in digital dentistry?

If you’re interested in the tremendous potential 3D printing technology holds, look no further than JUELL™ 3D. The JUELL™ 3D printer is at the forefront of digital dentistry advancements. Our printer is considered one of the fastest on the market today, providing patient-specific solutions in a matter of minutes. For example, the JUELL™ 3D-3 can print orthodontic models for complete clear aligner treatment in less than 18 minutes! The new generation of JUELL™ 3D is powered by an advanced software that optimizes accuracy.

JUELL™ 3D-3 surpasses the competition in precision and price. To learn more about our 3D printers, resins, software, and technical specifications, click here.